Aluminum

- Home

- Aluminum

Aluminium

Aluminum sheets are made from pure aluminum or aluminum alloys. Common alloying

elements include copper, magnesium, manganese, silicon, and zinc.

1000 Series: Pure aluminum (99% or higher), excellent corrosion resistance

and high thermal/electrical conductivity.

3000 Series: Alloyed with manganese, known for good corrosion resistance and

moderate strength.

5000 Series: Alloyed with magnesium, offers good corrosion resistance,

especially in marine environments, and high strength.

6000 Series: Alloyed with magnesium and silicon, balanced strength and

workability, good corrosion resistance.

7000 Series: Alloyed with zinc, very high strength, used in aerospace

applications.

| Alloy | UNS Number | Composition (%) | Density (g/cm³) | Melting Point (°C) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Applications |

|---|---|---|---|---|---|---|---|---|

| 1100 | A91100 | Al 99.0 min, Cu 0.05-0.20, Fe 0.95 max, Si 0.95 max, Zn 0.10 max, Mn 0.05 max | 2.71 | 643-657 | 90-140 | 34-85 | 10-30 | Chemical equipment, food processing, heat exchangers, decorative uses |

| 2024 | A92024 | Al 90.7-94.7, Cu 3.8-4.9, Mg 1.2-1.8, Mn 0.3-0.9, Fe 0.50 max, Si 0.50 max, Zn 0.25 max | 2.78 | 502-638 | 470-540 | 325-410 | 10-20 | Aerospace structures, truck wheels, aircraft components, automotive applications |

| 3003 | A93003 | Al 96.8-99.0, Mn 1.0-1.5, Fe 0.70 max, Si 0.60 max, Cu 0.05-0.20, Zn 0.10 max | 2.73 | 643-654 | 110-195 | 40-120 | 10-20 | Cookware, chemical equipment, storage tanks, heat exchangers |

| 5052 | A95052 | Al 95.7-97.7, Mg 2.2-2.8, Cr 0.15-0.35, Fe 0.40 max, Si 0.25 max, Cu 0.10 max, Zn 0.10 max | 2.68 | 607-650 | 230-295 | 193-260 | 10-20 | Marine environments, fuel tanks, pressure vessels, truck and trailer components |

| 6061 | A96061 | Al 95.8-98.6, Mg 0.8-1.2, Si 0.4-0.8, Cu 0.15-0.4, Cr 0.04-0.35, Fe 0.7 max, Zn 0.25 max | 2.70 | 582-652 | 241-310 | 145-276 | 8-17 | Structural applications, aerospace components, marine fittings, automotive frames |

| 7075 | A97075 | Al 87.1-91.4, Zn 5.1-6.1, Mg 2.1-2.9, Cu 1.2-2.0, Cr 0.18-0.28, Fe 0.50 max, Si 0.40 max | 2.81 | 477-635 | 510-570 | 430-505 | 5-11 | Aerospace structures, high-stress applications, military equipment, sports equipment |

| 6063 | A96063 | Al 97.5-99.3, Mg 0.45-0.9, Si 0.2-0.6, Fe 0.35 max, Cu 0.10 max, Zn 0.10 max, Mn 0.10 max, Cr 0.10 max | 2.70 | 615-655 | 186-240 | 110-145 | 12-18 | Architectural applications, window frames, irrigation tubing, railings |

| 3004 | A93004 | Al 94.8-97.4, Mn 1.0-1.5, Mg 0.8-1.3, Fe 0.7 max, Si 0.3 max, Cu 0.25 max, Zn 0.25 max | 2.73 | 630-655 | 220-275 | 180-240 | 12-20 | Beverage cans, roofing sheets, chemical equipment, storage tanks |

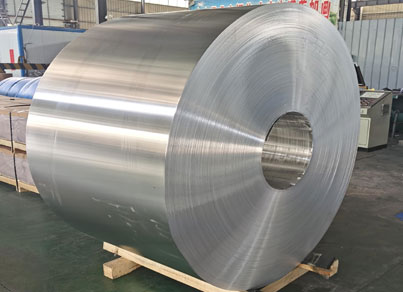

Aluminum coils are made from pure aluminum or aluminum alloys, often containing

elements like magnesium, manganese, silicon, and zinc to enhance specific

properties.

1000 Series: Nearly pure aluminum (99% or higher), offering excellent

corrosion resistance and high thermal/electrical conductivity.

3000 Series: Alloyed with manganese, known for good corrosion resistance and

moderate strength.

5000 Series: Alloyed with magnesium, providing good corrosion resistance,

especially in marine environments, and high strength.

6000 Series: Alloyed with magnesium and silicon, offering balanced strength

and workability with good corrosion resistance.

7000 Series: Alloyed with zinc, known for very high strength, commonly used

in aerospace applications.

| EN Number | Alloy Designation | Composition (%) | Density (g/cm³) | Melting Point (°C) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Applications |

|---|---|---|---|---|---|---|---|---|

| EN AW-1050A | Al 1050A | Al ≥ 99.5 | 2.71 | 660 | 60-100 | 20-45 | 25-35 | Electrical conductors, chemical industry |

| EN AW-1200 | Al 1200 | Al ≥ 99.0 | 2.71 | 660 | 60-110 | 30-50 | 25-35 | Chemical industry, food industry |

| EN AW-3003 | AlMn1Cu | Al 96.7, Mn 1.2-1.5, Cu ≤ 0.20 | 2.73 | 655 | 95-200 | 35-110 | 20-40 | Cooking utensils, heat exchangers |

| EN AW-5005 | AlMg1 | Al 97.0-99.5, Mg 0.5-1.1, Mn ≤ 0.20 | 2.70 | 650 | 100-145 | 30-50 | 10-20 | Architectural applications, anodizing |

| EN AW-5083 | AlMg4.5Mn0.7 | Al 92.4-95.6, Mg 4.0-4.9, Mn 0.4-1.0 | 2.66 | 570-640 | 275-350 | 125-200 | 10-15 | Marine environments, pressure vessels |

| EN AW-6061 | AlMg1SiCu | Al 95.8-98.6, Mg 0.8-1.2, Si 0.4-0.8, Cu 0.15-0.4 | 2.70 | 582-652 | 240-310 | 100-280 | 10-18 | Structural applications, automotive industry |

| EN AW-7075 | AlZn5.5MgCu | Al 87.1-91.4, Zn 5.1-6.1, Mg 2.1-2.9, Cu 1.2-2.0 | 2.81 | 477-635 | 450-560 | 370-480 | 5-11 | Aerospace, high-stress components |