Sheets & Plates

Nickel Sheets & Plates

Nickel sheets and plates are essential materials in various industries due to their exceptional properties, including high corrosion resistance, excellent mechanical strength, and superior thermal and electrical conductivity. This guide provides detailed information on nickel sheets and plates, covering their properties, types, applications, and benefits.

High Strength: Nickel sheets and plates maintain high mechanical strength and structural integrity under stress.

Nickel's superior thermal conductivity makes it ideal for applications requiring efficient heat transfer.

| Specification | EN Standard | Grade | Chemical Composition | Description |

|---|---|---|---|---|

| Nickel 200 | EN 2.4060 | UNS N02200 | Ni: 99.0% min, Fe: 0.4% max, Cu: 0.25% max, Mn: 0.35% max, S: 0.01% max, C: 0.15% max, Si: 0.1% max | Excellent corrosion resistance and high thermal and electrical conductivity. Used in chemical processing and electronics. |

| Nickel 201 | EN 2.4061 | UNS N02201 | Ni: 99.0% min, Fe: 0.4% max, Cu: 0.3% max, Mn: 0.35% max, S: 0.01% max, C: 0.02% max, Si: 0.1% max | Similar to Nickel 200 but with lower carbon content for better weldability. Used in chemical and petrochemical industries. |

| Nickel 205 | EN 2.4068 | UNS N02205 | Ni: 99.0% min, Fe: 0.2% max, Cu: 0.3% max, Mn: 0.35% max, S: 0.01% max, C: 0.02% max, Si: 0.1% max | High purity nickel with improved mechanical properties. Used in applications requiring high thermal stability. |

| Nickel 270 | EN 2.4632 | UNS N02600 | Ni: 99.0% min, Fe: 0.3% max, Cu: 0.3% max, Mn: 0.5% max, S: 0.01% max, C: 0.02% max, Si: 0.1% max | Used in high-temperature applications. Provides good resistance to oxidation and thermal stability. |

| Nickel 400 | EN 2.4360 | UNS N04400 | Ni: 63-70%, Cu: 28-34%, Fe: 2.5% max, Mn: 2.0% max, Si: 0.5% max, C: 0.3% max | Excellent resistance to seawater, hydrofluoric acid, and sulfuric acid. Used in marine and chemical processing industries. |

| Nickel 405 | EN 2.4642 | UNS N04405 | Ni: 62-70%, Cu: 28-34%, Fe: 2.5% max, Mn: 2.0% max, Si: 0.5% max, C: 0.3% max, Al: 0.2-0.4%, Ti: 0.1-0.4% | Similar to Nickel 400 but with improved strength and hardness due to the addition of aluminum and titanium. |

Monel Sheets & Plates

Monel is a family of nickel-copper alloys known for their exceptional corrosion resistance and high strength. Monel sheets and plates are commonly used in industries that require materials to withstand harsh environments, including marine, chemical, and oil and gas applications.

ASTM B127: Standard specification for nickel-copper alloy (Monel 400) plate, sheet, and strip.

ASTM B168: Standard specification for Monel K-500 sheet, strip, and plate.

ASME SB127: ASME specification for Monel 400 plate, sheet, and strip for pressure vessels.

ASME SB168: ASME specification for Monel K-500 sheet, strip, and plate for pressure vessels.

| Specification | EN Standard | Grade | Chemical Composition | Description |

|---|---|---|---|---|

| Monel 400 | EN 2.4360 | UNS N04400 | Ni: 63-70%, Cu: 28-34%, Fe: 2.5% max, Mn: 2.0% max, Si: 0.5% max, C: 0.3% max | Excellent resistance to seawater, hydrofluoric acid, and sulfuric acid. Used in marine, chemical, and hydrocarbon processing industries. |

| Monel K500 | EN 2.4375 | UNS N05500 | Ni: 63-70%, Cu: 27-33%, Fe: 2.0% max, Mn: 1.5% max, Si: 0.5% max, C: 0.25% max, Al: 2.3-3.15%, Ti: 0.35-0.85% | Combines excellent corrosion resistance of Monel 400 with greater strength and hardness. Used in marine, oil and gas, and pump applications. |

| Monel R405 | EN 2.4605 | UNS N04405 | Ni: 63-70%, Cu: 27-33%, Fe: 2.5% max, Mn: 2.0% max, Si: 0.5% max, C: 0.30% max, Al: 0.3-0.6%, Ti: 0.15-0.35% | Similar to Monel 400 with added machinability due to the presence of sulfur. Used in applications requiring high machinability and strength. |

| Monel 401 | EN 2.4361 | UNS N04401 | Ni: 63-70%, Cu: 28-34%, Fe: 2.0% max, Mn: 1.0% max, Si: 0.5% max, C: 0.30% max, Al: 2.0-2.5%, Ti: 0.25-0.35% | Offers high strength and excellent corrosion resistance. Used in marine, chemical, and petrochemical applications. |

Inconel Sheets & Plates

Inconel sheets and plates offer outstanding resistance to corrosion in a wide range of environments,

including oxidizing and reducing conditions, alkaline solutions, and high-temperature atmospheres.

This corrosion resistance makes them suitable for applications exposed to aggressive chemicals,

acids, and seawater.

Inconel alloys retain their mechanical strength and structural integrity at elevated temperatures,

making them ideal for use in high-temperature applications such as gas turbine components, heat

exchangers, and furnace parts.

| Specification | EN Standard | Grade | Chemical Composition | Description |

|---|---|---|---|---|

| Inconel 600 | EN 2.4816 | UNS N06600 | Ni: 72.0-78.0%, Cr: 14.0-17.0%, Fe: Balance, Mn: 1.0% max, Si: 0.5% max, C: 0.15% max | High temperature and oxidation resistance. Used in aerospace, chemical processing, and heat treatment applications. |

| Inconel 718 | EN 2.4668 | UNS N07718 | Ni: 50.0-55.0%, Cr: 17.0-21.0%, Fe: Balance, Mo: 2.8-3.3%, Ti: 0.65-1.15%, Al: 0.2-0.8%, C: 0.08% max | High strength and oxidation resistance at elevated temperatures. Used in aerospace and gas turbine components. |

| Inconel 725 | EN 2.4663 | UNS N07725 | Ni: 58.0-65.0%, Cr: 19.0-21.0%, Mo: 4.0-5.0%, Fe: Balance, Ti: 0.6-1.2%, Al: 0.2-0.8%, C: 0.05% max | High strength and excellent corrosion resistance in severe environments. Used in oil and gas, aerospace, and chemical processing. |

| Inconel X-750 | EN 2.4669 | UNS N07750 | Ni: 70.0-75.0%, Cr: 14.0-17.0%, Fe: Balance, Mo: 0.5-1.0%, Ti: 0.6-1.2%, Al: 0.2-0.6%, C: 0.08% max | High strength and oxidation resistance. Used in aerospace, gas turbines, and chemical processing industries. |

| Inconel 693 | EN 2.4617 | UNS N06993 | Ni: 58.0-63.0%, Cr: 18.0-21.0%, Mo: 3.0-4.0%, Ti: 0.5-1.0%, Al: 0.1-0.6%, C: 0.05% max, Fe: Balance | High strength and excellent resistance to oxidation and corrosion. Used in aerospace and high-temperature applications. |

| Inconel 600 | EN 2.4816 | UNS N06600 | Ni: 72.0-78.0%, Cr: 14.0-17.0%, Fe: Balance, Mn: 1.0% max, Si: 0.5% max, C: 0.15% max | High temperature and oxidation resistance. Used in aerospace, chemical processing, and heat treatment industries. |

| Inconel 625 | EN 2.4856 | UNS N06625 | Ni: 58.0-63.0%, Cr: 20.0-23.0%, Mo: 8.0-10.0%, Fe: Balance, Mn: 0.5% max, Si: 0.5% max, C: 0.10% max | Excellent fatigue and thermal-fatigue strength. Used in aerospace, marine, and chemical processing applications. |

| Inconel 800 | EN 1.4876 | UNS N08800 | Ni: 30.0-35.0%, Cr: 19.0-23.0%, Fe: Balance, Mn: 1.0% max, Si: 0.5% max, C: 0.1% max | Good resistance to oxidation and carburization. Used in heat exchangers, industrial furnace components, and petrochemical processing. |

| Inconel 825 | EN 2.4858 | UNS N08825 | Ni: 38.0-46.0%, Cr: 19.5-23.5%, Fe: Balance, Mo: 2.5-3.5%, Ti: 0.6-1.2%, Al: 0.2% max, C: 0.05% max, Cu: 1.5-3.0% | Excellent resistance to both reducing and oxidizing acids, stress-corrosion cracking, and localized attack. Used in chemical processing, pollution control, oil and gas recovery, acid production. |

Hastelloy Sheets & Plates

Hastelloy sheets and plates exhibit exceptional resistance to corrosion in aggressive environments,

including sulfuric acid, hydrochloric acid, seawater, and acidic solutions containing chlorides.

This corrosion resistance makes them suitable for applications exposed to harsh chemicals and

corrosive atmospheres.

Hastelloy C276: The most widely used Hastelloy alloy, known for its versatility and superior corrosion

resistance.

Hastelloy C22: Offering enhanced resistance to pitting, crevice corrosion, and oxidizing environments.

Hastelloy B2: Exceptional resistance to hydrochloric acid at all concentrations and temperatures.

| Specification | EN Standard | Grade | Chemical Composition | Description |

|---|---|---|---|---|

| Hastelloy B-2 | EN 2.4600 | UNS N10665 | Ni: Balance, Mo: 28.0-30.0%, Fe: 0.5% max, Cr: 0.5% max, C: 0.01% max, Si: 0.1% max, Mn: 0.5% max | Excellent resistance to hydrochloric acid and other reducing environments. Used in chemical processing. |

| Hastelloy B-3 | EN 2.4590 | UNS N10675 | Ni: Balance, Mo: 27.0-30.0%, Fe: 2.0% max, Cr: 1.0% max, C: 0.01% max, Si: 0.2% max, Mn: 1.0% max | Improved resistance to hydrochloric acid and thermal stability compared to B-2. Used in chemical processing and reactors. |

| Hastelloy C-22 | EN 2.4602 | UNS N06022 | Ni: Balance, Cr: 20.0-22.0%, Mo: 13.0-15.0%, W: 2.0-3.0%, Co: 2.5% max, Fe: 2.5% max, C: 0.015% max | Outstanding resistance to oxidizing and reducing environments. Used in chemical processing, aerospace, and marine applications. |

| Hastelloy C-276 | EN 2.4819 | UNS N10276 | Ni: Balance, Cr: 15.0-17.0%, Mo: 15.0-17.0%, W: 3.0-4.0%, Fe: 4.0-7.0%, C: 0.01% max, Si: 0.08% max | Excellent resistance to a wide range of chemical environments, including oxidizers and chlorides. Used in chemical and petrochemical industries. |

| Hastelloy X | EN 2.4665 | UNS N06002 | Ni: Balance, Cr: 20.0-23.0%, Mo: 0.5-1.0%, Fe: 17.0-21.0%, Co: 1.0% max, C: 0.15% max, Si: 0.2% max | High strength and oxidation resistance at elevated temperatures. Used in gas turbines and aerospace components. |

| Hastelloy B-4 | EN 2.4668 | UNS N10630 | Ni: Balance, Mo: 28.0-30.0%, Fe: 2.0% max, Cr: 0.5% max, C: 0.01% max, Si: 0.1% max, Mn: 1.0% max | Enhanced resistance to hydrochloric acid and other aggressive environments. Used in chemical processing and handling equipment. |

Super Duplex Sheets & Plates

Super duplex stainless steel is characterized by its dual-phase microstructure, consisting of

approximately equal parts of austenite and ferrite phases.

Super duplex sheets and plates exhibit exceptional corrosion resistance in chloride-rich environments,

such as seawater and chemical processing applications.

Super duplex stainless steel sheets and plates boast outstanding mechanical properties, including high

tensile and yield strength, as well as excellent impact toughness.

Super duplex sheets and plates can be readily fabricated using conventional methods such as cutting,

bending, and welding.

| Specification | EN Standard | Grade | Chemical Composition | Description |

|---|---|---|---|---|

| Super Duplex 2507 | EN 1.4410 | UNS S32750 | Ni: 7.0-9.0%, Cr: 24.0-26.0%, Mo: 3.0-5.0%, Fe: Balance, Mn: 1.0% max, Si: 1.0% max, C: 0.03% max | Superior strength and corrosion resistance, especially in chloride environments. Used in oil and gas, chemical processing, and marine applications. |

| Super Duplex 32760 | EN 1.4501 | UNS S32760 | Ni: 8.0-10.0%, Cr: 24.0-26.0%, Mo: 3.0-5.0%, Fe: Balance, Mn: 1.0% max, Si: 1.0% max, C: 0.03% max | High resistance to pitting and crevice corrosion. Used in chemical processing, desalination, and marine industries. |

| Super Duplex 32750 | EN 1.4410 | UNS S32750 | Ni: 7.0-9.0%, Cr: 24.0-26.0%, Mo: 3.0-5.0%, Fe: Balance, Mn: 1.0% max, Si: 1.0% max, C: 0.03% max | Excellent combination of high strength and corrosion resistance. Used in petrochemical and marine environments. |

| Super Duplex 2507 | EN 1.4501 | UNS S32760 | Ni: 8.0-10.0%, Cr: 24.0-26.0%, Mo: 3.0-5.0%, Fe: Balance, Mn: 1.0% max, Si: 1.0% max, C: 0.03% max | Enhanced mechanical properties and corrosion resistance. Ideal for demanding applications in harsh environments. |

Duplex Sheets & Plates

Duplex Steel plates contains high Chromium (18% - 28%) these plates are very high corrosion resistant, higher strength, excellent impact toughness at the same time its Nickel content is lower (5 - 6%). It is majorly used in chemical processing units, transportation, oil & gas exploration, pressure vessels, tanks, marine etc.

| Specification | EN Standard | Grade | Chemical Composition | Description |

|---|---|---|---|---|

| Duplex 2205 | EN 1.4462 | UNS S32205 | Ni: 4.5-6.5%, Cr: 21.0-23.0%, Mo: 2.5-3.5%, Fe: Balance, Mn: 1.2% max, Si: 1.0% max, C: 0.03% max | Good resistance to stress corrosion cracking and high strength. Used in chemical processing, oil and gas, and marine environments. |

| Duplex 2507 | EN 1.4410 | UNS S32750 | Ni: 7.0-9.0%, Cr: 24.0-26.0%, Mo: 3.0-5.0%, Fe: Balance, Mn: 1.0% max, Si: 1.0% max, C: 0.03% max | Superior strength and corrosion resistance, especially in chloride environments. Used in oil and gas, chemical processing, and marine applications. |

| Duplex 2304 | EN 1.4362 | UNS S32304 | Ni: 4.5-6.5%, Cr: 21.0-23.0%, Mo: 0.5-1.0%, Fe: Balance, Mn: 2.0% max, Si: 1.0% max, C: 0.03% max | Cost-effective duplex stainless steel with good resistance to corrosion and high strength. Used in general industrial applications. |

| Duplex 2507 | EN 1.4501 | UNS S32760 | Ni: 8.0-10.0%, Cr: 24.0-26.0%, Mo: 3.0-5.0%, Fe: Balance, Mn: 1.0% max, Si: 1.0% max, C: 0.03% max | High resistance to pitting and crevice corrosion. Used in chemical processing, desalination, and marine industries. |

| Duplex 255 | EN 1.4507 | UNS S32550 | Ni: 8.0-10.0%, Cr: 24.0-26.0%, Mo: 6.0-7.0%, Fe: Balance, Mn: 1.0% max, Si: 1.0% max, C: 0.03% max | Excellent resistance to corrosion in harsh environments. Used in chemical processing and high-temperature applications. |

Stainless Steel Sheets & Plates

Stainless steel plate are hot rolled and is very versatile and used in a variety of applications. It is primarily selected for its corrosion resistance, high tensile strength, temperature resistant, long lasting, easy formability & attractive appearance. Typical uses of stainless steel plate include for construction, food industry, breweries, infrastructure, vessels & tanks manufacturing, process industry, dairy, pharmaceutical, fabrication, etc. Stainless steel sheets, also commonly known as Cold Rolled Products, can be moulded into shapes for making tanks, vessels, fabrication, home décor, cookware etc.

| Stainless Steel Grade | EN Standard | UNS Number | Chemical Composition | Description |

|---|---|---|---|---|

| 304 (ASTM A240 Gr. TP 304) | EN 1.4301 | UNS S30400 | Ni: 8-10.5%, Cr: 18-20%, Fe: Balance, Mn: 2% max, Si: 1% max, P: 0.045% max, S: 0.03% max, C: 0.08% max | Excellent corrosion resistance and formability. Used in food processing, chemical, and architectural applications. |

| 304L (ASTM A240 Gr. TP 304L) | EN 1.4307 | UNS S30403 | Ni: 8-12%, Cr: 18-20%, Fe: Balance, Mn: 2% max, Si: 1% max, P: 0.045% max, S: 0.03% max, C: 0.03% max | Similar to 304 but with lower carbon content for better weldability. Used in chemical processing and storage tanks. |

| 304LN (ASTM A240 Gr. TP 304LN) | - | UNS S30453 | Ni: 8-12%, Cr: 18-20%, N: 0.10-0.16%, Fe: Balance, Mn: 2% max, Si: 1% max, P: 0.045% max, S: 0.03% max, C: 0.03% max | Nitrogen-enhanced version of 304L for higher strength. Used in chemical and cryogenic applications. |

| 309 (ASTM A240 Gr. TP 309) | - | UNS S30900 | Ni: 12-15%, Cr: 22-24%, Fe: Balance, Mn: 2% max, Si: 1% max, P: 0.045% max, S: 0.03% max, C: 0.20% max | High temperature oxidation resistance. Used in furnace parts and high-temperature containers. |

| 309S (ASTM A240 Gr. TP 309S) | - | UNS S30908 | Ni: 12-15%, Cr: 22-24%, Fe: Balance, Mn: 2% max, Si: 1% max, P: 0.045% max, S: 0.03% max, C: 0.08% max | Improved oxidation resistance and high-temperature strength. Used in furnace parts, high-temperature containers. |

| 309H (ASTM A240 Gr. TP 309H) | - | UNS S30909 | Ni: 12-15%, Cr: 22-24%, Fe: Balance, Mn: 2% max, Si: 1% max, P: 0.045% max, S: 0.03% max, C: 0.04-0.10% | Similar to 309S but with higher carbon for improved high-temperature strength. |

| 310H (ASTM A240 Gr. TP 310H) | - | UNS S31009 | Ni: 19-22%, Cr: 24-26%, Fe: Balance, Mn: 2% max, Si: 1.5% max, P: 0.045% max, S: 0.03% max, C: 0.04-0.10% | Similar to 310S but with higher carbon content for improved high-temperature strength. |

| 316 (ASTM A240 Gr. TP 316) | EN 1.4401 | UNS S31600 | Ni: 10-14%, Cr: 16-18%, Mo: 2-3%, Fe: Balance, Mn: 2% max, Si: 1% max, P: 0.045% max, S: 0.03% max, C: 0.08% max | Superior corrosion resistance especially against chlorides. Used in marine, chemical, and medical applications. |

| 316L (ASTM A240 Gr. TP 316L) | EN 1.4404 | UNS S31603 | Ni: 10-14%, Cr: 16-18%, Mo: 2-3%, Fe: Balance, Mn: 2% max, Si: 1% max, P: 0.045% max, S: 0.03% max, C: 0.03% max | Similar to 316 but with lower carbon content for improved weldability. Used in marine, chemical, and medical applications. |

| 316H (ASTM A240 Gr. TP 316H) | - | UNS S31609 | Ni: 10-14%, Cr: 16-18%, Mo: 2-3%, Fe: Balance, Mn: 2% max, Si: 1% max, P: 0.045% max, S: 0.03% max, C: 0.04-0.10% | Similar to 316 but with higher carbon content for improved high-temperature strength. |

| 316LN (ASTM A240 Gr. TP 316LN) | EN 1.4429 | UNS S31653 | Ni: 10-14%, Cr: 16-18%, Mo: 2-3%, N: 0.10-0.16%, Fe: Balance, Mn: 2% max, Si: 1% max, P: 0.045% max, S: 0.03% max, C: 0.03% max | Nitrogen-enhanced version of 316L for higher strength. Used in chemical and nuclear applications. |

| 316Ti (ASTM A240 Gr. TP 316Ti) | EN 1.4571 | UNS S31635 | Ni: 10-14%, Cr: 16-18%, Mo: 2-3%, Ti: 0.5%, Fe: Balance, Mn: 2% max, Si: 1% max, P: 0.045% max, S: 0.03% max, C: 0.08% max | Titanium stabilized for improved resistance to intergranular corrosion. Used in high-temperature applications. |

| 317 (ASTM A240 Gr. TP 317) | - | UNS S31700 | Ni: 11-15%, Cr: 18-20%, Mo: 3-4%, Fe: Balance, Mn: 2% max, Si: 1% max, P: 0.045% max, S: 0.03% max, C: 0.08% max | Higher molybdenum content for improved corrosion resistance. Used in chemical processing and paper mill equipment. |

| 317L (ASTM A240 Gr. TP 317L) | EN 1.4438 | UNS S31703 | Ni: 11-15%, Cr: 18-20%, Mo: 3-4%, Fe: Balance, Mn: 2% max, Si: 1% max, P: 0.045% max, S: 0.03% max, C: 0.03% max | Higher molybdenum content and low carbon for improved corrosion resistance and weldability. Used in chemical processing and paper mill equipment. |

| 321 (ASTM A240 Gr. TP 321) | EN 1.4541 | UNS S32100 | Ni: 9-12%, Cr: 17-19%, Ti: 0.7%, Fe: Balance, Mn: 2% max, Si: 1% max, P: 0.045% max, S: 0.03% max, C: 0.08% max | Stabilized with titanium for improved resistance to intergranular corrosion. Used in high-temperature applications. |

| 321H (ASTM A240 Gr. TP 321H) | EN 1.4878 | UNS S32109 | Ni: 9-12%, Cr: 17-19%, Ti: 0.7%, Fe: Balance, Mn: 2% max, Si: 1% max, P: 0.045% max, S: 0.03% max, C: 0.04-0.10% | Similar to 321 but with higher carbon content for improved high-temperature strength. |

| 347 (ASTM A240 Gr. TP 347) | EN 1.4550 | UNS S34700 | Ni: 9-13%, Cr: 17-20%, Nb: 10xC min, Fe: Balance, Mn: 2% max, Si: 1% max, P: 0.045% max, S: 0.03% max, C: 0.08% max | Stabilized with niobium for improved resistance to intergranular corrosion. Used in high-temperature and welded applications. |

| 347H (ASTM A240 Gr. TP 347H) | EN 1.4961 | UNS S34709 | Ni: 9-13%, Cr: 17-20%, Nb: 10xC min, Fe: Balance, Mn: 2% max, Si: 1% max, P: 0.045% max, S: |

Alloy Steel Sheets & Plates

Alloy steel sheets and plates are composed of iron as the base metal, with significant additions

of alloying elements such as chromium, nickel, molybdenum, and vanadium.

Alloy steel sheets and plates boast excellent mechanical properties, including high tensile and

yield strength, as well as good ductility and toughness.

Depending on the alloy composition, alloy steel sheets and plates offer varying degrees of corrosion

resistance.

Alloy steel sheets and plates can be readily fabricated using standard techniques such as cutting, bending,

and welding.

| Specification | EN Standard | Grade | Chemical Composition | Description |

|---|---|---|---|---|

| Alloy Steel AISI 4140 | EN 1.7225 | UNS G41400 | Ni: 0.8-1.1%, Cr: 0.8-1.1%, Mo: 0.15-0.25%, Fe: Balance, Mn: 0.75-1.0%, Si: 0.15-0.35%, C: 0.38-0.43% | High strength and toughness. Used in automotive, machinery, and tooling applications. |

| Alloy Steel AISI 4340 | EN 1.6511 | UNS G43400 | Ni: 1.65-2.0%, Cr: 0.8-1.1%, Mo: 0.2-0.3%, Fe: Balance, Mn: 0.6-0.8%, Si: 0.15-0.35%, C: 0.38-0.43% | High tensile strength and impact toughness. Used in aerospace, automotive, and heavy-duty machinery. |

| Alloy Steel AISI 8620 | EN 1.6523 | UNS G86200 | Ni: 1.0-1.4%, Cr: 0.5-0.8%, Mo: 0.15-0.25%, Fe: Balance, Mn: 0.6-0.9%, Si: 0.2-0.35%, C: 0.18-0.23% | Good case hardening properties. Used in gears, shafts, and other high-strength components. |

| Alloy Steel AISI 9310 | EN 1.6511 | UNS G93100 | Ni: 3.0-3.5%, Cr: 0.8-1.2%, Mo: 0.2-0.3%, Fe: Balance, Mn: 0.6-0.8%, Si: 0.2-0.3%, C: 0.1-0.15% | High core strength and toughness with good hardenability. Used in aircraft components and high-stress applications. |

| Alloy Steel AISI 52100 | EN 1.3505 | UNS G52100 | Ni: 0.3% max, Cr: 1.4-1.6%, Mo: 0.1% max, Fe: Balance, Mn: 0.6-0.9%, Si: 0.15-0.35%, C: 0.98-1.1% | High hardness and wear resistance. Commonly used in ball bearings, gears, and high-speed tools. |

Carbon Steel Sheets & Plates

Carbon steel sheets and plates are essential materials in various industries due to their strength,

versatility, and affordability.

Low Carbon Steel: Contains up to 0.3% carbon, offering good weldability and formability.

Medium Carbon Steel: Contains 0.3% to 0.6% carbon, balancing strength and ductility.

High Carbon Steel: Contains more than 0.6% carbon, providing exceptional hardness and

strength but less ductility.

Sheets: Thin, flat pieces usually less than 6mm thick, used in automotive panels, construction,

and general fabrication.

Plates: Thicker than sheets, commonly over 6mm, employed in structural applications, machinery,

and heavy equipment manufacturing.

| Specification | EN Standard | Grade | Chemical Composition | Description |

|---|---|---|---|---|

| Carbon Steel S235 | EN 1.0038 | UNS K02001 | Ni: 0.0-0.1%, Cr: 0.0-0.3%, Mn: 0.6-0.9%, Fe: Balance, C: 0.14-0.22% | Structural steel with good weldability and strength. Used in construction and engineering applications. |

| Carbon Steel S275 | EN 1.0044 | UNS K02500 | Ni: 0.0-0.1%, Cr: 0.0-0.3%, Mn: 0.6-0.9%, Fe: Balance, C: 0.16-0.24% | Versatile structural steel with good weldability and impact resistance. Used in various structural applications. |

| Carbon Steel S355 | EN 1.0545 | UNS K03500 | Ni: 0.0-0.1%, Cr: 0.0-0.3%, Mn: 0.6-0.9%, Fe: Balance, C: 0.22-0.26% | High strength and good weldability. Used in heavy-duty structural applications and in the construction industry. |

| Carbon Steel C45 | EN 1.0503 | UNS G10450 | Ni: 0.0-0.4%, Cr: 0.0-0.3%, Mn: 0.6-0.9%, Fe: Balance, C: 0.42-0.50% | Medium carbon steel with good machinability and wear resistance. Used in manufacturing mechanical components. |

| Carbon Steel 1045 | EN 1.1191 | UNS G10450 | Ni: 0.0-0.4%, Cr: 0.0-0.3%, Mn: 0.6-0.9%, Fe: Balance, C: 0.43-0.50% | High strength and hardness, often used in gears, shafts, and other mechanical components. |

Aluminum Sheets & Plates

Aluminum sheets and plates are primarily composed of aluminum, with small amounts of other elements

such as copper, magnesium, silicon, and zinc added for strength and other properties.

Pure Aluminum (1000 series): High corrosion resistance, excellent weldability, and formability.

Low strength.

Aluminum-Manganese Alloys (3000 series): Good formability, moderate strength, and corrosion

resistance.

Aluminum-Silicon Alloys (4000 series): Good flowability and weldability, used for welding or

brazing.

Aluminum-Magnesium Alloys (5000 series): Excellent corrosion resistance, high strength, suitable

for marine applications.

Aluminum-Zinc Alloys (7000 series): High strength and toughness, often used in aerospace applications.

| Specification | EN Standard | Grade | Chemical Composition | Description |

|---|---|---|---|---|

| Aluminum 1050 | EN 1.0550 | UNS A91050 | Ni: 0.0-0.05%, Cr: 0.05-0.20%, Fe: 0.4%, Mn: 0.05-0.2%, Si: 0.25%, C: 0.05% max | High purity aluminum with excellent corrosion resistance and good workability. Used in chemical and food processing industries. |

| Aluminum 2011 | EN 3.1655 | UNS A92011 | Ni: 0.0-0.30%, Cu: 4.0-4.9%, Pb: 0.5-1.0%, Fe: 0.7%, Si: 0.5%, Mn: 0.6%, Cr: 0.1% | Excellent machinability, used in precision machining and intricate parts. |

| Aluminum 2024 | EN 3.1355 | UNS A92024 | Ni: 0.0-0.3%, Cu: 3.8-4.9%, Fe: 0.5%, Mn: 0.3-0.9%, Si: 0.5%, Cr: 0.1%, Zn: 0.25% | High strength and good fatigue resistance. Commonly used in aerospace applications and structural components. |

| Aluminum 6061 | EN 3.3214 | UNS A96061 | Ni: 0.0-0.1%, Mg: 0.8-1.2%, Si: 0.4-0.8%, Fe: 0.7%, Cu: 0.15-0.4%, Cr: 0.04-0.35%, Zn: 0.25% | Good mechanical properties and excellent corrosion resistance. Used in aerospace, automotive, and structural applications. |

| Aluminum 7075 | EN 3.4365 | UNS A97075 | Ni: 0.1-0.2%, Cu: 1.2-1.6%, Mg: 2.1-2.9%, Zn: 5.1-6.1%, Fe: 0.5%, Mn: 0.3%, Si: 0.4%, Cr: 0.2% | High strength and good fatigue resistance. Widely used in aerospace and high-stress applications. |

Titanium Sheets & Plates

Titanium sheets and plates are primarily composed of titanium, with small amounts of other

elements like aluminum, vanadium, or iron added to improve mechanical properties.

Commercially Pure Titanium (CP): Contains a low percentage of other elements, typically 99%

pure titanium. Grades 1 to 4 are common.

Titanium Alloys: Incorporate alloying elements such as aluminum, vanadium, or iron to enhance

specific properties like strength or corrosion resistance. Grades 5 (Ti-6Al-4V) and 23

(Ti-6Al-4V ELI) are popular titanium alloys.

| Specification | EN Standard | Grade | Chemical Composition | Description |

|---|---|---|---|---|

| Titanium Grade 1 | EN 3.7025 | UNS R50250 | Ni: 0.0-0.1%, Fe: 0.3%, O: 0.18%, C: 0.08%, H: 0.015%, Ti: Balance | Pure titanium with excellent corrosion resistance and high ductility. Used in chemical processing and aerospace applications. |

| Titanium Grade 2 | EN 3.7035 | UNS R50400 | Ni: 0.0-0.1%, Fe: 0.3%, O: 0.25%, C: 0.08%, H: 0.015%, Ti: Balance | Good corrosion resistance and formability. Commonly used in marine environments and medical devices. |

| Titanium Grade 5 | EN 3.7165 | UNS R56400 | Ni: 0.0-0.3%, Fe: 0.3%, O: 0.2%, C: 0.08%, H: 0.015%, Al: 4.0-4.5%, V: 3.5-4.5%, Ti: Balance | High strength and moderate corrosion resistance. Used in aerospace, automotive, and high-performance applications. |

| Titanium Grade 7 | EN 3.7165 | UNS R52400 | Ni: 0.2-0.5%, Fe: 0.3%, O: 0.2%, C: 0.08%, H: 0.015%, Ti: Balance | Improved corrosion resistance in reducing environments. Used in chemical processing and marine applications. |

| Titanium Grade 9 | EN 3.7165 | UNS R56500 | Ni: 0.0-0.3%, Fe: 0.3%, O: 0.25%, C: 0.08%, H: 0.015%, Al: 0.5-0.8%, V: 0.1-0.3%, Ti: Balance | High strength with good weldability. Used in aerospace and automotive industries for lightweight structural components. |

Nimonic Sheets & Plates

Nimonic alloys primarily consist of nickel along with varying amounts of chromium, cobalt,

titanium, aluminum, and other elements.

Different grades of Nimonic alloys are available, including Nimonic 75, Nimonic 80A, Nimonic 90,

Nimonic 105, and others, each offering specific properties for different applications.

Sheets: Thin, flat pieces with thicknesses typically ranging from 0.5mm to 6mm.

Plates: Thicker than sheets, usually over 6mm.

| Specification | EN Standard | Grade | Chemical Composition | Description |

|---|---|---|---|---|

| Nimonic 75 | EN 2.4964 | UNS N06075 | Ni: Balance, Cr: 15.0-16.0%, Co: 1.0-1.5%, Mo: 2.0-2.5%, Al: 0.4-0.6%, Ti: 0.4-0.6%, Fe: 2.0% max, C: 0.15% max | High temperature strength and oxidation resistance. Used in gas turbine engines and aerospace components. |

| Nimonic 80A | EN 2.4631 | UNS N07080 | Ni: Balance, Cr: 19.0-21.0%, Co: 1.0-1.5%, Mo: 2.0-3.0%, Al: 0.4-0.6%, Ti: 0.4-0.6%, Fe: 2.0% max, C: 0.15% max | Excellent resistance to oxidation and high-temperature strength. Used in jet engines and high-performance applications. |

| Nimonic 90 | EN 2.4632 | UNS N07090 | Ni: Balance, Cr: 19.0-21.0%, Co: 1.0-2.0%, Mo: 2.0-3.0%, Al: 0.5-0.7%, Ti: 0.4-0.6%, Fe: 2.0% max, C: 0.15% max | High strength at elevated temperatures and good oxidation resistance. Used in aerospace and industrial gas turbines. |

| Nimonic 263 | EN 2.4660 | UNS N07263 | Ni: Balance, Cr: 20.0-22.0%, Co: 15.0-17.0%, Mo: 2.5-3.0%, Al: 0.5-0.7%, Ti: 0.2-0.4%, Fe: 1.0% max, C: 0.08% max | Excellent high-temperature strength and corrosion resistance. Used in advanced aerospace and high-temperature applications. |

| Nimonic 105 | EN 2.4630 | UNS N06010 | Ni: Balance, Cr: 14.0-16.0%, Co: 1.5-2.5%, Mo: 0.5-1.0%, Al: 0.2-0.4%, Ti: 0.2-0.4%, Fe: 2.0% max, C: 0.15% max | Good high-temperature strength and oxidation resistance. Used in high-performance aerospace applications. |

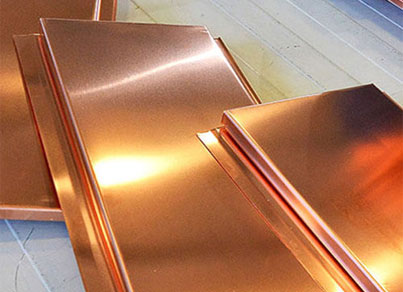

Copper Sheets & Plates

Copper plates has an excellent electric conductivity, high thermal conductivity, and good resistance to corrosion. It is used in variety of industry across the world marine, electrical parts, steam condensers, heat exchangers, boilers, tanks, cooling industry, chillers, military, architectural use & home décor.

| Specification | EN Standard | Grade | Chemical Composition | Description |

|---|---|---|---|---|

| Copper C10100 | EN 2.0060 | UNS C10100 | Ni: 0.0%, Cu: Balance, O: 0.02%, Fe: 0.04%, Pb: 0.001% | High purity copper with excellent electrical and thermal conductivity. Used in electrical applications and electronics. |

| Copper C10200 | EN 2.0060 | UNS C10200 | Ni: 0.0%, Cu: Balance, O: 0.02%, Fe: 0.05%, Pb: 0.001% | Slightly higher oxygen content than C10100, maintaining high conductivity. Used in electrical and electronic applications. |

| Copper C11000 | EN 2.0090 | UNS C11000 | Ni: 0.0%, Cu: Balance, O: 0.03%, Fe: 0.04%, Pb: 0.01% | Electrolytic tough pitch copper with high electrical conductivity. Commonly used in electrical wiring and connectors. |

| Copper C21000 | EN 2.0990 | UNS C21000 | Ni: 0.6-0.8%, Cu: Balance, Fe: 0.04%, Pb: 0.05%, Zn: 0.1% | Brass with improved strength and machinability. Used in plumbing fittings and industrial applications. |

| Copper C26000 | EN 2.0401 | UNS C26000 | Ni: 0.0%, Cu: Balance, Zn: 70.0-72.0%, Fe: 0.2%, Pb: 0.05% | Cartridge brass with good machinability and strength. Used in automotive and hardware applications. |

Brass Plates

The composition of brass, generally 66% copper and 34% zinc, makes it a favourable substitute for copper as it exhibits greater resistance to corrosion and is more affordable. Brass is not as hard as bronze, and so is not suitable for most weapons and tools. Applications for brass plate includes construction equipment’s, ammunition, door locks, brackets, door plates, domestic interior fittings, electrical and plumbing components and architectural fascia's.

| Specification | EN Standard | Grade | Chemical Composition | Description |

|---|---|---|---|---|

| Brass C22000 | EN 2.0321 | UNS C22000 | Ni: 0.0%, Cu: Balance, Zn: 78.0-82.0%, Fe: 0.3%, Pb: 0.05% | Plain brass with good machinability and corrosion resistance. Commonly used in architectural and decorative applications. |

| Brass C26000 | EN 2.0401 | UNS C26000 | Ni: 0.0%, Cu: Balance, Zn: 70.0-72.0%, Fe: 0.2%, Pb: 0.05% | Cartridge brass with good machinability and strength. Used in plumbing fittings, automotive, and hardware applications. |

| Brass C27000 | EN 2.0402 | UNS C27000 | Ni: 0.0%, Cu: Balance, Zn: 60.0-63.0%, Fe: 0.4%, Pb: 0.05% | Yellow brass with good corrosion resistance and machinability. Used in coins, musical instruments, and fittings. |

| Brass C28000 | EN 2.0450 | UNS C28000 | Ni: 0.0-0.3%, Cu: Balance, Zn: 59.0-63.0%, Fe: 0.5%, Pb: 0.05% | Muntz metal with high strength and good corrosion resistance. Used in marine and industrial applications. |

| Brass C36000 | EN 2.0402 | UNS C36000 | Ni: 0.0%, Cu: Balance, Zn: 61.0-63.0%, Fe: 0.1%, Pb: 3.7-4.0% | Free-cutting brass with excellent machinability. Widely used in precision turned parts and automotive components. |