Copper

- Home

- Copper

Copper

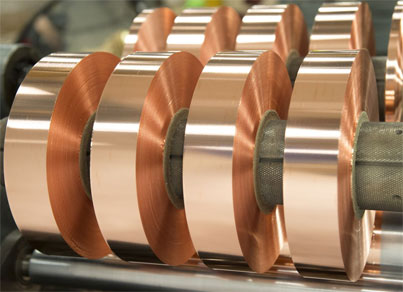

We offer enamelled copper wires and cables. Our vast range is available in different lengths and thicknesses and also as per the client's requirements. Having superior mechanical properties, these wires very well meet with all the requirement of the clients. Our wires and cables have excellent tensile strength and can easily resist high temperature and other adverse conditions.

| Alloy | UNS Number | Composition (%) | Density (g/cm³) | Melting Point (°C) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Applications |

|---|---|---|---|---|---|---|---|---|

| C10100 (OFHC) | C10100 | Cu 99.99 min, O 0.0005 max | 8.94 | 1083 | 210-275 | 69-103 | 40-50 | Electrical conductors, vacuum tubes, microwave tubes |

| C11000 (ETP) | C11000 | Cu 99.90 min, O 0.04 max | 8.94 | 1083 | 210-275 | 69-103 | 40-50 | Electrical wiring, electrical connectors, architectural uses |

| C12200 (DHP) | C12200 | Cu 99.90 min, P 0.015-0.040 | 8.94 | 1083 | 210-275 | 69-103 | 40-50 | Plumbing, HVAC, heat exchangers |

| C21000 (Gilding) | C21000 | Cu 95, Zn 5 | 8.83 | 1083 | 345-465 | 105-345 | 15-30 | Jewelry, architectural trim, medals |

| C23000 (Red Brass) | C23000 | Cu 84-86, Zn 14-16 | 8.53 | 1025-1030 | 330-420 | 90-150 | 30-40 | Plumbing accessories, pump cylinders, marine hardware |

| C26000 (Cartridge Brass) | C26000 | Cu 68.5-71.5, Zn 28.5-31.5 | 8.53 | 904-932 | 315-560 | 95-275 | 40-65 | Ammunition casings, radiator cores, architectural hardware |

| C36000 (Free-Cutting Brass) | C36000 | Cu 60-63, Zn 35.5-38.5, Pb 2.5-3.7 | 8.44 | 885-905 | 380-480 | 90-180 | 20-36 | Precision machining, screw machine parts, valve components |

| C51000 (Phosphor Bronze) | C51000 | Cu 94.8, Sn 5.0, P 0.2 | 8.88 | 1040-1080 | 515-620 | 280-345 | 5-25 | Springs, fasteners, electrical connectors |

| C70600 (90-10 Cu-Ni) | C70600 | Cu 88.6, Ni 10.0, Fe 1.4 | 8.94 | 1145-1230 | 485-625 | 125-250 | 30-45 | Marine applications, heat exchangers, desalination plants |

| C71500 (70-30 Cu-Ni) | C71500 | Cu 69.5, Ni 30.0, Fe 0.4, Mn 0.8 | 8.94 | 1150-1235 | 550-690 | 150-310 | 25-45 | Marine hardware, condensers, evaporators |

| C72500 (High-Nickel Cu) | C72500 | Cu 65.0, Ni 25.0, Sn 10.0 | 8.94 | 1093-1135 | 620-765 | 350-520 | 10-25 | High-strength fasteners, marine shafts, electrical contacts |

| C93200 (Bearing Bronze) | C93200 | Cu 83, Sn 7, Pb 7, Zn 3 | 8.9 | 1040-1075 | 230-270 | 105-140 | 10-20 | Bearings, bushings, machine parts |

| C95400 (Aluminum Bronze) | C95400 | Cu 85, Al 10-11.5, Fe 3-4, Mn 0.5 max | 7.63 | 1020-1037 | 620-720 | 275-450 | 12-25 | Aerospace, marine applications, high-strength fasteners |

| C95800 (Nickel Aluminum Bronze) | C95800 | Cu 79, Al 9-11, Fe 4-5, Ni 4-5, Mn 1.5 max | 7.6 | 1035-1045 | 655-765 | 320-450 | 12-20 | Marine hardware, pumps, valves, high-strength components |

With the support of a team, we manufacture a premium grade of Copper Coated Stitching Wire & Galvansied Stitching Wire. We can provide our range as per the requirement of customers. Our range is available in the following sizes:

Flat Gauges: 12X25, 12X22, 13 X 25, 14 X 25 & 17X25

Round Gauges: 18, 19, 20, 21, 22, 23, 24, 25, 26, 27, 28

NARROW FLAT: 21X23, 21X24, 21X25, 20X22, 20X23, 20X24, 19X22, and 19X25

| EN Number | Alloy Designation | Composition (%) | Density (g/cm³) | Melting Point (°C) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Applications |

|---|---|---|---|---|---|---|---|---|

| CW004A | Cu-ETP | Cu ≥ 99.90 | 8.94 | 1083 | 200-400 | 40-180 | 30-60 | Electrical conductors, wiring, cables, busbars |

| CW008A | Cu-OF | Cu ≥ 99.95 | 8.94 | 1083 | 220-400 | 50-180 | 35-60 | Electronic components, vacuum devices, electrical conductors |

| CW009A | Cu-OFE | Cu ≥ 99.99 | 8.94 | 1083 | 220-400 | 50-180 | 35-60 | High-vacuum applications, electronic components |

| CW024A | Cu-DHP | Cu ≥ 99.90 | 8.94 | 1083 | 200-350 | 40-150 | 30-50 | Plumbing, heating, gas fittings, medical gas applications |

| CW021A | Cu-HCP | Cu ≥ 99.95 | 8.94 | 1083 | 220-400 | 50-180 | 35-60 | Electrical conductors, transformer windings |

| CW025A | Cu-ETP1 | Cu ≥ 99.95 | 8.94 | 1083 | 220-400 | 50-180 | 35-60 | Electrical conductors, wiring, cables, busbars |

| CW105C | CuCr1Zr | Cu 98.0-99.2, Cr 0.5-1.2, Zr 0.03-0.3 | 8.90 | 1080-1083 | 400-550 | 300-450 | 10-25 | Spot welding electrodes, resistance welding, electrical contacts |

| CW106C | CuCr1 | Cu 98.8-99.2, Cr 0.6-1.2 | 8.90 | 1080-1083 | 400-550 | 300-450 | 10-25 | Electrical contacts, conductive springs, welding electrodes |

| CW107C | CuCr1Zr0.1 | Cu 98.8-99.2, Cr 0.6-1.2, Zr 0.03-0.15 | 8.90 | 1080-1083 | 400-550 | 300-450 | 10-25 | Electrical contacts, conductive springs, welding electrodes |

| CW118C | CuNi2Si | Cu 97.3-99.0, Ni 1.4-2.2, Si 0.3-0.8 | 8.85 | 1080-1083 | 500-750 | 300-500 | 10-20 | Electrical connectors, springs, welding equipment |

| CW219C | CuCo2Be | Cu 98.0-98.5, Co 2.0-2.8, Be 0.4-0.7 | 8.90 | 1080-1083 | 600-800 | 400-600 | 5-15 | High strength electrical components, springs |